NDT SERVICES

Visual Inspection

CORROCONT LTD’s corrosion engineers and specialised NDT professionals perform visual inspection in accordance with key international standards such as API 653 and EEMUA 159.

Vacuum Box Testing

This test method covers procedures for detecting or locating leaks. It is most useful on piping systems, pressure vessels, storage tanks. Three types of boxes (test frames) are used by CORROCONT, depending on the type of weld: butt weld, overlap weld, or corner fillet weld.

Ultrasonic inspection

Ultrasonic inspection uses short wavelength sound waves with high frequency to detect flaws or measure material thickness. CORROCONT performs ultrasonic testing of storage tanks, pipelines and other metal structures by its engineers holding at least UT level II certificate.

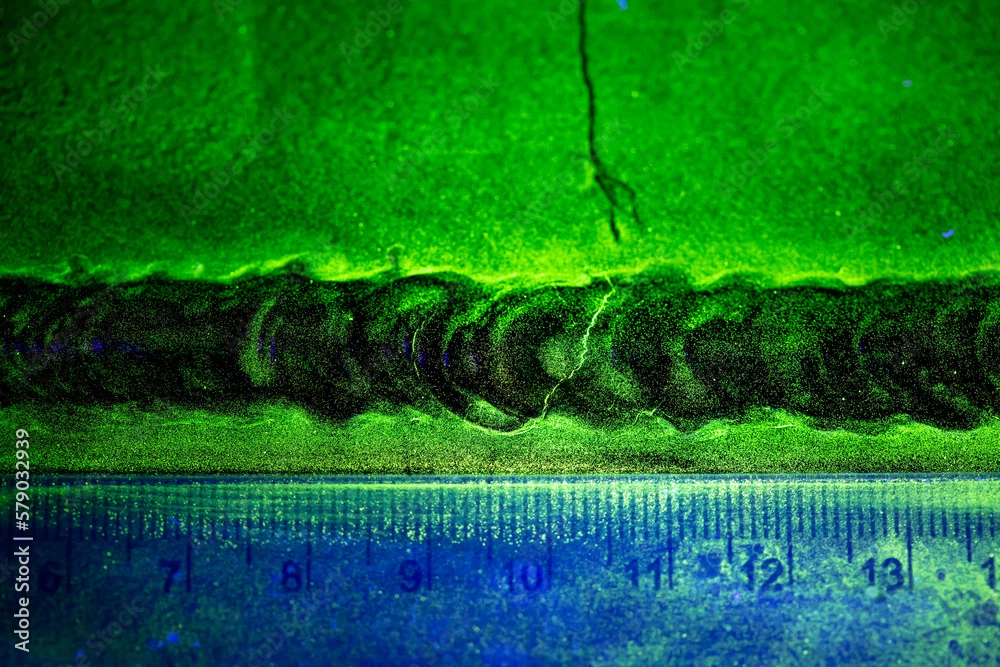

Magnetic Particle Inspection

This method is suitable for detection of surface and near surface discontinuities in ferromagnetic material, mainly ferritic steels, and iron. The technique not only detects those defects which are not normally visible to the unaided eye, but also renders easily visible those defects which would otherwise require close scrutiny of the surface.

LFET-Low Frequency Electromagnetic Testing

CORROCONT has a unique LFET scanner family: TST-27M: tank bottom scanner, MWS-1, MWS-32 climbing scanners installed on the crawler with magnetic wheels: tank shell and pipeline motorised scanner and PS-DX: pipeline hand scanner with our in-house developed evaluation software. Our inspection method has been used since 1997 by many oil and gas companies all over the world. These unique devices have been developed and manufactured by CORROCONT. Each device has own software to manage measured data and produce "online corrosion map" with "on- site report".

Dye Penetrant Inspection

Liquid penetration inspection is a method that is used to reveal surface breaking flaws by bleed out of a coloured or fluorescent dye from the flaw. Penetrant inspection can be used on any material. It is essential that the material is carefully cleaned first, otherwise the penetrant will not be able to get into the defect. If surface penetrant is not fully removed, misleading indications will result.

FLOORMAP3DI ADVANCED MFL TANK INSPECTION WITH STARS TOP & BOTTOM DEFECT DISCRIMINATION

Silverwing’s Floormap3Di with STARS, MFLi (intensity) and Dynamic Cursor is the highest performance Magnetic Flux Leakage (MFL) storage tank inspection system on the market today. The Floormap3Di has the highest density of MFL sensors, coupled with advanced signal processing to deliver greater accuracy and probability of detection at maximum efficiency. The innovative STARS technology (patent pending) adds an additional set of sensors to detect variation in magnetic field strength caused by top side defects, and combines this with traditional MFL indications to identify top or bottom location. The Floormap3Di has a total of 256 sensors, enhancing lateral resolution to detect smaller defects, and reduce sensitivity to defect orientation. The top surface discrimination works effectively through up to 6 mm (1/4”) coating, enabling effective tank inspection without coating removal.